Precise Dosing and Temperature Control: Automation for Challenging Processes in Medical Technology with Rehm

posted 7th February 2025

Since 1990, Rehm Thermal Systems has been manufacturing production equipment for various industries. The majority of their 10,000+ systems are installed in high-end applications, including the medical technology sector.

They currently employ more than 700 people and place great importance on long-term partnerships. As a medium-sized company, Rehm operates successfully in 24 countries and offers an extensive service network. They support customers and interested parties with technological enquiries, selecting the right production process and defining the necessary parameters. The Technology Center, located at the headquarters in Blaubeuren, southern Germany, also serves this purpose. In addition to their standard product portfolio, their custom machine-building capabilities enable them to meet individual customer needs even more effectively.

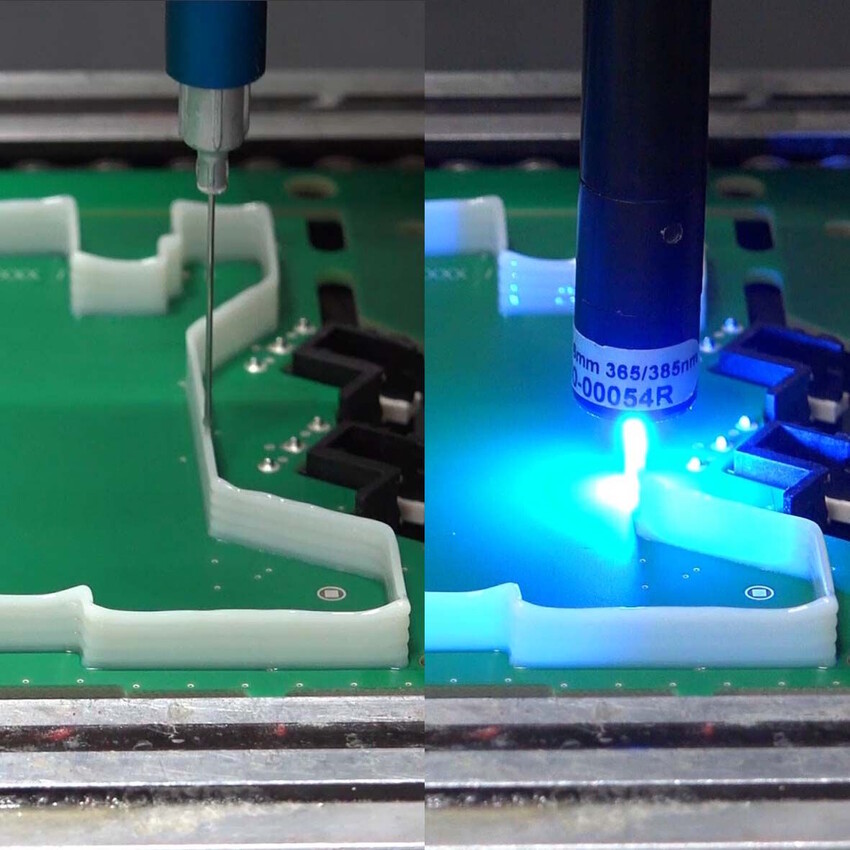

For the medical technology sector, they manufacture innovative and scalable automation solutions designed to help their customers stand out. Rehm Thermal Systems' production equipment excels in bonding, potting, coating, drying, tempering, and soldering, offering exceptional quality, durability, and process reliability—all while ensuring maximum customization. Whether it's pacemakers, catheters, or MRI devices, they have a solution.

To address skilled labor shortages and increase production cycle efficiency, they develop fully integrated customized production line solutions with various levels of automation. They collaborate with long-standing partners who are experts in specialized areas, such as flexible and delicate component handling.

Complete traceability of all products and the ability to reproduce the entire production process—even years later—is essential. Their systems feature multiple interfaces that allow for long-term tracking of all process and product data. These interfaces can be individually customized through the in-house software development—horizontally between machines and vertically to an MES (Manufacturing Execution System).

Rehm systems are also equipped with our proprietary ViCON software, which offers intuitive touch operation and step-by-step guided programming. The ViCON-Connect variant enables the connection of all Rehm machines—both locally and globally—allowing programming and operation from remote workstations.

Visit them at Medical Technology Germany in Ulm on July 9–10, 2025, to learn more about automation solutions for complex production processes. Their experts, Jasmin Fuchs and Christoph Maier, will be available at Stand 120 to provide consultation and discuss your specific projects.

For more information, check out our Medical Technology brochure.