Individual Enclosures for Laboratory and Medical Technology

posted 26th February 2025

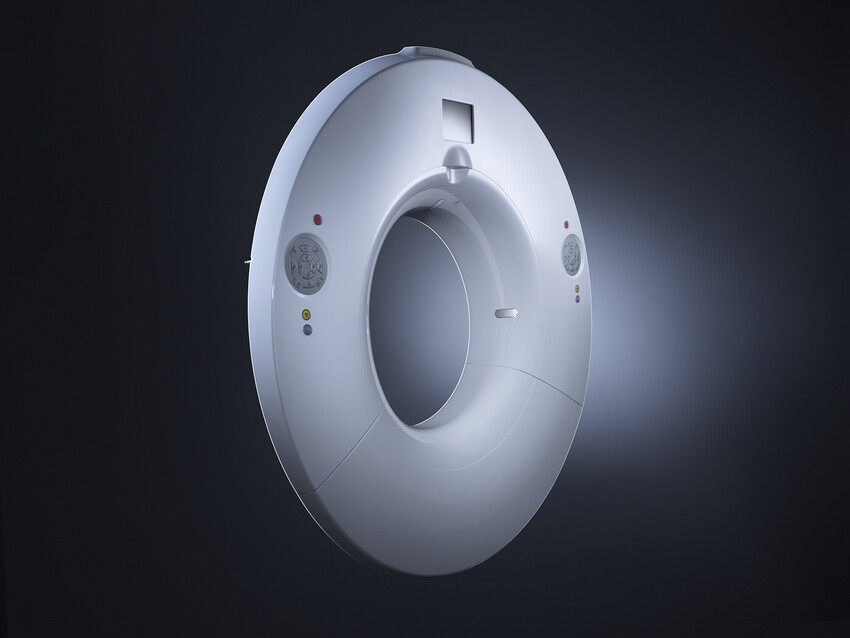

First impressions count – even with medical and laboratory devices. Design and enclosure quality shape the brand image and significantly influence customer perception.

What does the device of the future look like? Which surfaces withstand cleaning cycles? Which material meets the highest temperature requirements? These questions are crucial for the success of a product. However, keeping track of constantly evolving manufacturing technologies and new materials is a challenge. The good news: Quality can be planned, controlled, and ensured.

From Idea to Series Production

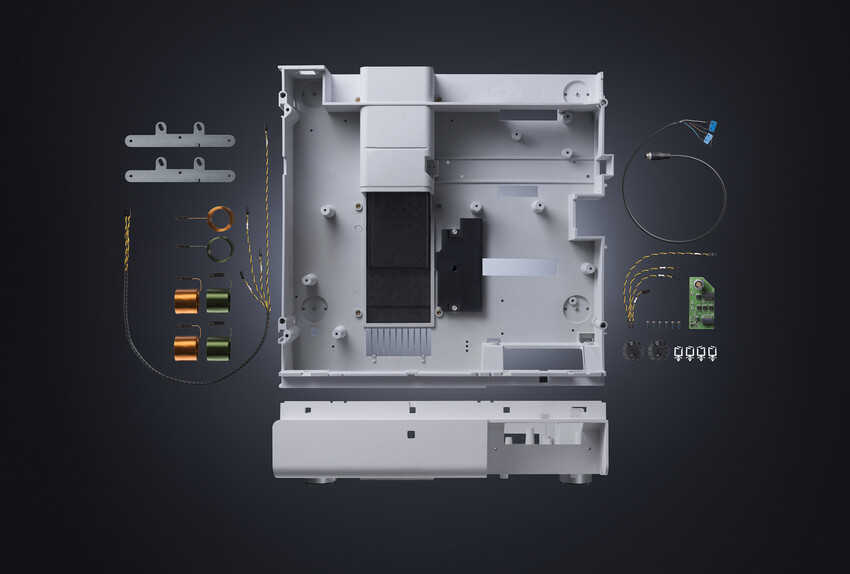

The path to the perfect enclosure includes design, material selection, function integration, surface, certification, and time-to-market. Industry-specific standards must also be met. The first step involves component design and visualization in CAD. Rapid prototyping allows for early production of prototypes and pre-series parts – quickly and flexibly. Precise planning and stable series delivery ensure a secure supply chain.

Fried Turns Your Idea into Reality

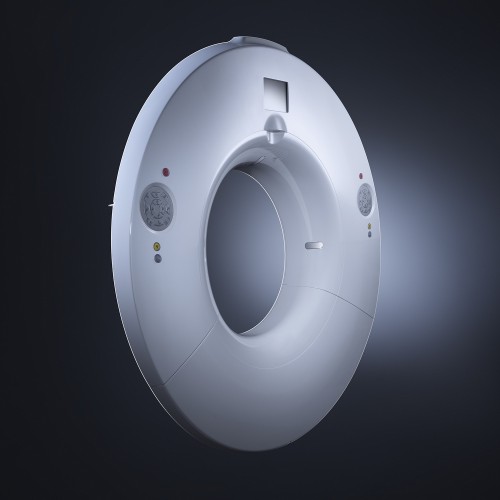

Whether it's man-sized injection-molded parts for CT scanners or plastic components for other medical devices – Fried develops precision for laboratories, practices, and operating rooms. As a partner to many world market leaders, the Swabian family business realizes customer-specific solutions made of plastic in any batch size – from small to very large series, in low and high quantities.

About Fried Kunststofftechnik

With over 45 years of experience in plastics technology, painting, and electromechanical assembly, and more than 250 employees at the Urbach site, Fried is one of the leading companies in the industry. Continuous investments in the latest production facilities enable Fried to offer economical and innovative solutions at the highest level. Certifications DIN EN ISO 9001, DIN EN ISO 14001, and DIN EN ISO 50001 stand for quality, sustainability, and responsible resource use.

Premium quality made in Germany – for the international market.

*Fried Kunststofftechnik GmbH will be exhibiting at Medical Technology Germany 2025 on stand 119